In the current swift manufacturing industry, custom injection molding has emerged as a key solution for businesses in search of personalized production methods. Such an innovative technique facilitates companies to create highly specific parts and components that meet their distinct specifications and quality standards. As industries increasingly seek tailored solutions that enhance efficiency and reduce costs, the relevance of custom injection molding continues to grow.

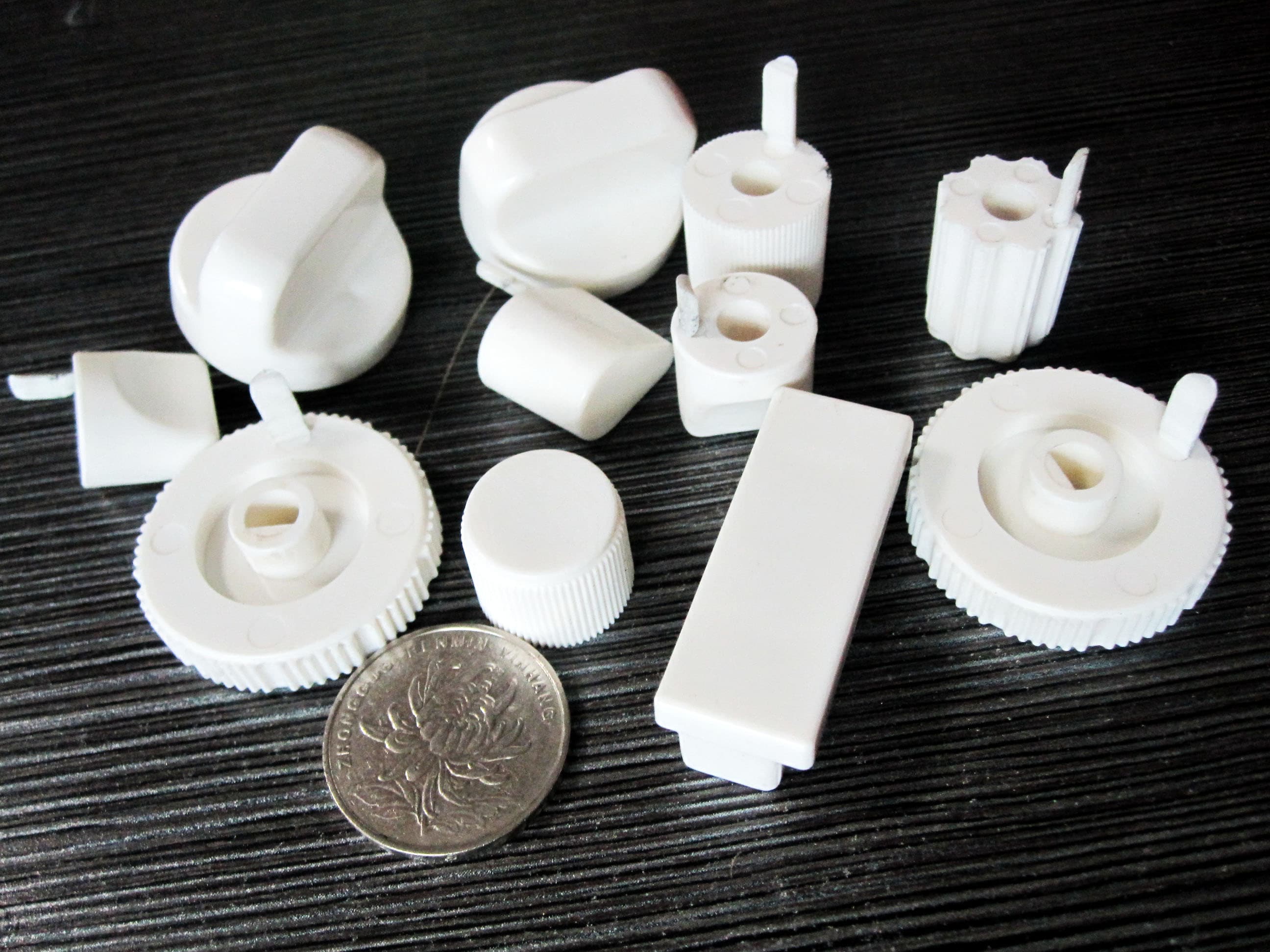

At the core, custom injection molding is a manufacturing process that involves pumping molten material into a mold to produce intricate designs and shapes. This method not just offers precision and consistency but also enables a wide variety of materials to be used, meeting different application needs. As companies work to set themselves in cutthroat markets, adopting custom injection molding can lead to significant advantages, from more rapid turnaround times to greater flexibility in design.

Advantages of Custom Injection Molding

Tailored injection molding offers substantial advantages for manufacturers seeking to produce high-quality parts smoothly. One of the primary benefits is the ability to create elaborate geometries that would be challenging or unattainable to obtain with alternative manufacturing methods. This capability allows businesses to create novel products that meet particular functional needs, thereby boosting their market position in the field.

In furthermore to design versatility, custom injection molding also supports cost efficiency, particularly for mass production runs. The process minimizes material waste by using exact amounts of plastic in each cycle, which causes a lowering in overall production costs. Moreover, once the injection mold is produced, the high-speed nature of the process allows for rapid production of thousands of identical parts, significantly boosting output and lowering lead times.

Another crucial benefit is the exceptional reliability and quality of the finished products. Custom injection molding produces parts that maintain strict tolerances and uniformity, which is essential for industries where precision is paramount, such as automotive and medical devices. This potential to reproduce exact specifications reliably boosts product reliability and customer satisfaction, finally fostering brand commitment and lasting success in the industry.

Utilizations Across Industries

Personalized injectable molding holds a critical part in numerous sectors, delivering distinct answers that address specialized requirements. In the auto field, for instance, it is employed to create complex parts such as instrument panels, cabin accessories, and engine elements. The capacity to produce light yet robust elements enables manufacturers improve gas mileage and meet safety standards, while also providing flexible designs that can enhance the design quality of cars.

In the medical industry, tailored injectable forming guarantees that healthcare products and components are created with exactness and dependability. Devices like disposable syringes, surgical tools, and casings for gadgets are enhanced by the precision that this method delivers. Moreover, the application of biocompatible materials in the molding process guarantees that the final products meet stringent health regulations, making them secure for medical application.

The consumer electronics industry also extensively makes use of custom injection molding for items such as smartphone cases, plugs, and remote controls. The technique enables the creation of detailed forms and designs while maintaining quality standards. With the swift growth of advancements in tech, the capacity to tailor and quickly create tech gadgets is essential for companies to remain in the game and meet consumer demands.

A Outlook of Molding

The outlook of injection mold technology is ready for major advancements driven by technological advancements and growing consumer needs. As industries increasingly transition towards greener methods, custom injection molding processes are being modified to incorporate sustainable materials, such as biodegradable materials and recycled materials. This change not only tackles ecological issues but also appeals to consumers' rising preference for products that match with their principles.

Automation and digitalization are also assuming crucial roles in the development of injection molding. Intelligent technologies, including the connected devices and machine learning, are allowing manufacturers to optimize production processes, reduce waste, and increase precision. These developments will result in quicker lead times, improved quality control, and the ability to rapidly adjust to shifting consumer preferences, making custom injection molding more responsive to market dynamics.

Moreover, as product customization becomes ever essential, customized injection molding will need to adjust to reduced batch sizes and more complex designs. This adaptability will enable possibilities for industries such as automotive, aerospace, and consumer electronics to explore new designs and functionalities. With constant innovation, the outlook of injection molding will not only fulfill the expectations of the current market but also establish a basis for a more streamlined and green manufacturing landscape.